Wilcoxon Sensing Technologies, formerly known as Wilcoxon Research Inc., was founded in 1960, a manufacturer and global supplier of vibration monitoring solutions. With a proven track record of success and a long history of providing advanced solutions for underwater environments, Wilcoxon offers a wide range of high-quality industrial vibration sensors, transmitters and instrumentation for accurate and reliable vibration measurements in many applications.

Solutions for a wide range of industrial, professional and underwater applications. Accuracy and quality from concept to production and to delivery. Results-oriented industry partners. Reliable, high-performance and cost-effective products.

Other descriptions

Accelerometer

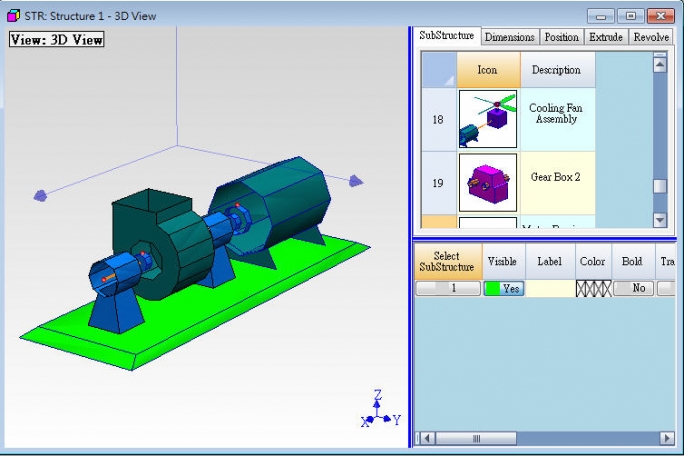

- Multi-functional accelerometer: With a large frequency range, it can measure most industrial ma-chinery. With a predictive maintenance system, it can measure rotating equipment such as the motor, fan, pump, gear box, machine tool spindle, rotor, compressor, and so on. Recommended models: 775A, 777/777B, 780A, 782A, 784A, 785A, 786A, 786F, 787A, 787F, 788A, 793, 797, S100C SNAP, S100CS SNAP and SK104

- High frequency accelerometer: To measure high speed mechanisms such as gears and bearings of mechanical equipment. Recommended models: 712F, 732A/732AT, 736/736T

- Low frequency accelerometer: For monitoring and over-range measurement of manufacturing conditions in the petrochemical, paper, and machine tool industries. Also, it can be used for blowers, cooling towers, semiconductor equipment, building structure inspection, etc. Recommended models: 786-500, 793L, 797L, 799LF and 799M

- High temperature accelerometer: temperatures up to 150℃ (302℉) and 260℃ (500℉). Recommended models: 793-6, 797-6, 376, 376/CC701HT

- 3-axis accelerometer: provides multi-directional value collection. Recommended models: 993A and 993B

4-20mA Loop Powered Sensors (LPS®)

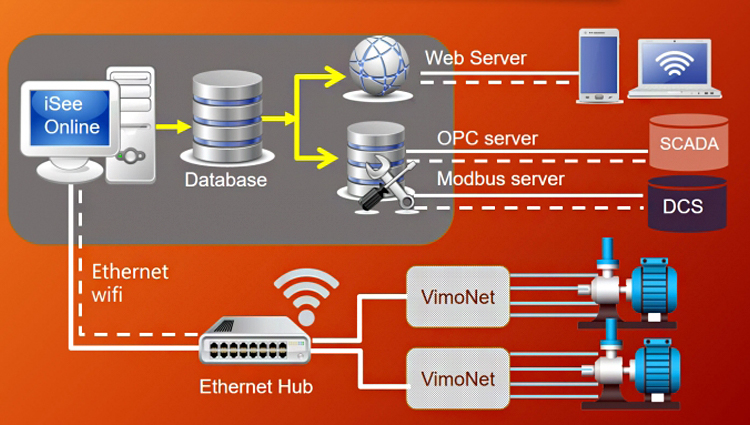

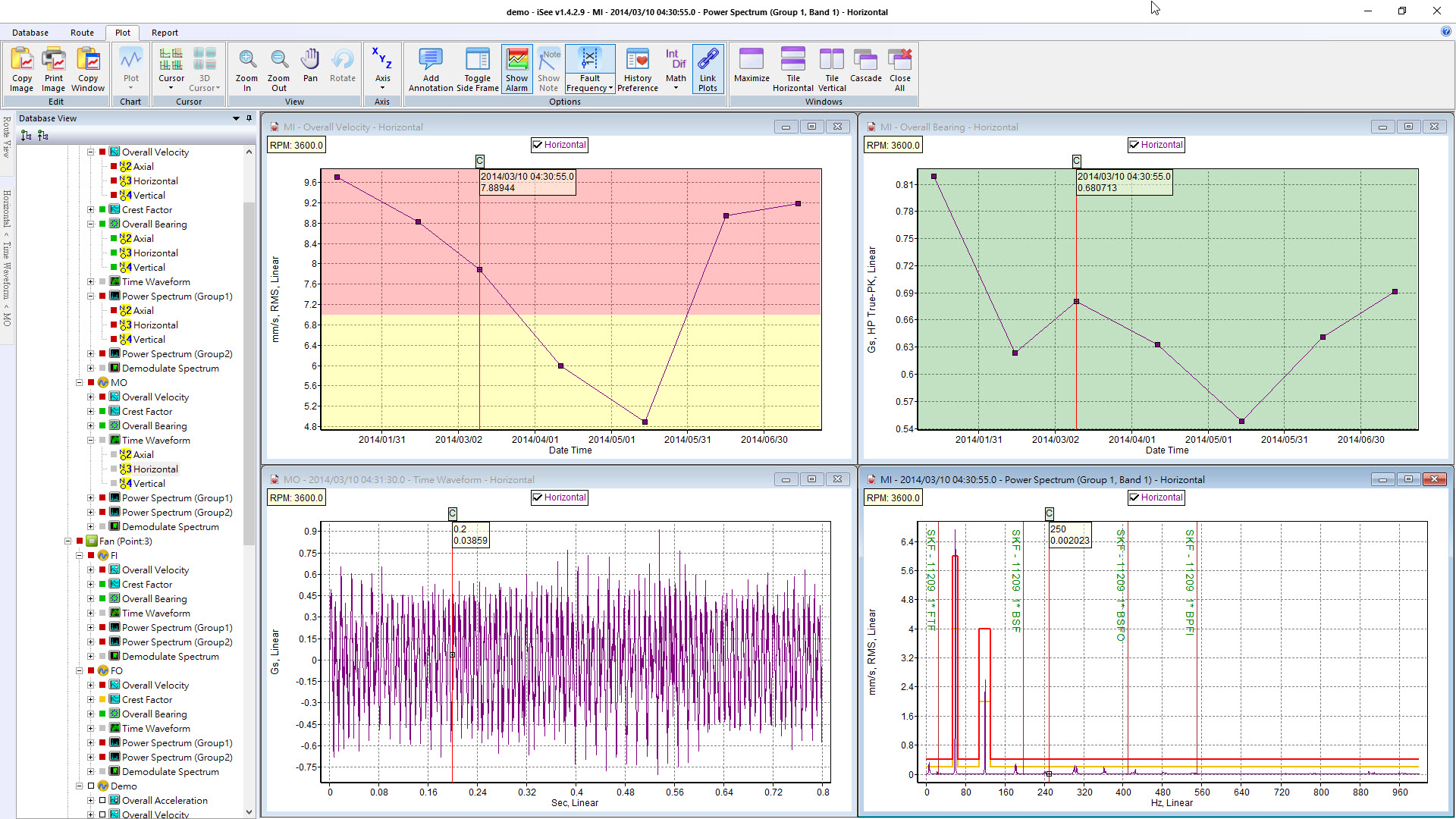

Vibration values can be provided to PLC or DCS network control interfaces. The acceleration, speed, temperature and other numerical signals of the machine and equipment can be linked to the control system to understand the curve changes and achieve condition monitoring and predictive maintenance work.

Recommended models: PC420, PC421, PC423, PC425 and PC427

Exclusive sensors

- Helicopter special sensors

- Leak detector for water pipes

- TEDS(Transducer Electronic Data Sheets)

- Speed and pressure sensors

- Seismic micro-vibration measurement sensors. Recommended models: 731A/P31, 731-207

- Underwater measurement sensor

- Dynamic balance

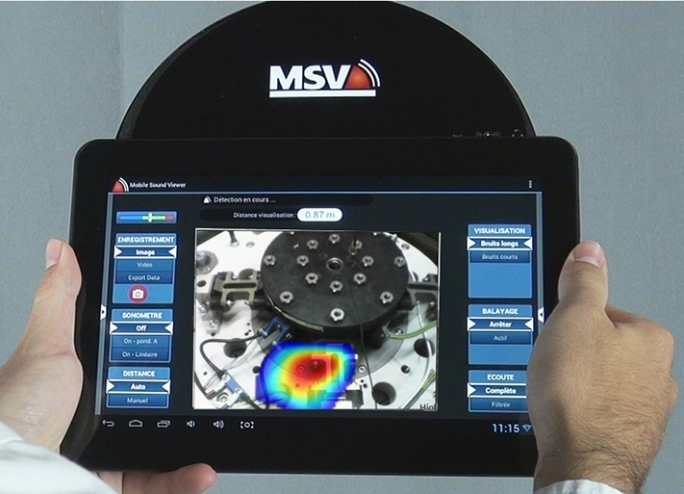

- Vibration inspection

- Modal and operational vibration measurement

- Vehicle comfort measurement

- Floor micro vibration and stiffness measurement

- Vibration online monitoring

- Machine tool heat deformation measurement and compensation

- Machine tool cutting chatter analysis

- Machine tool cutting process optimization

- Machine crash prevention

- Machine tool 5-axis accuracy inspection

- Machine tool spindle dynamic rotation accuracy measurement

- Low frequency vibration measurement of bridges and buildings

- Noise barrier measurement

- Pipeline gas leakage volume measurement

- Vehicle crash test

- Slop and landslide monitoring

- Semiconductor robot arm monitoring

- Semiconductor process monitoring and quality measurement

- Vibration measurement