vPod Pro the Newest Mechanical Health Status Analyzer/Data Collector on the Market

vPod Pro the Newest Mechanical Health Status Analyzer/Data Collector on the Market

G-TECH has laucned vPod Pro, a new generation of health checker, which has received a great response from the market due to its innovative design, and we would like to introduce its main features.

Innovative Design of A52-IR Vibration/Temperature Sensor

A52-IR is a dual output sensor innovatively designed by G-TECH. In addition to the internal high-performance vibration sensor, the A52-IR is equipped with an infrared temperature sensor in the bottom center opening and a strong magnetic holder below. This design allows the portable analyzer to measure both temperature and vibration simultaneously, and the use of a strong magnetic holder ensures the transmission and accurate measurement of high frequency signals from bearings or gears. This new design is the only one of its kind in the world, and it was first used in the new vPod Pro.

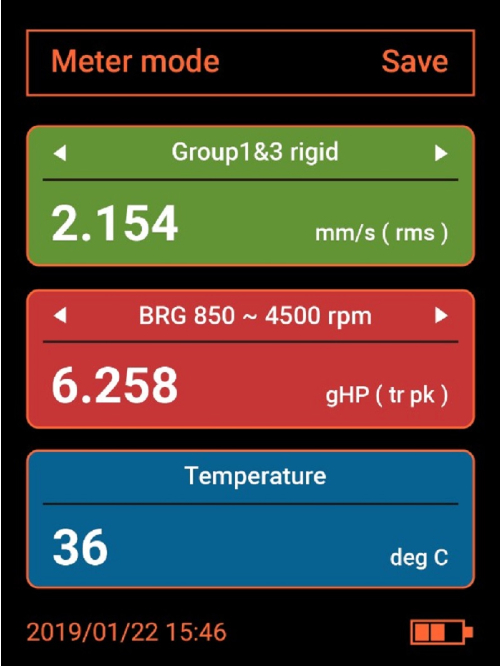

Simultaneous Display of Three Values

With the A52-IR, the vPod Pro can display three mechanical values at once: vibration value, bearing status and temperature, with a background color indicating the alarm status of the value, allowing the user to know at a glance how the device is operating.

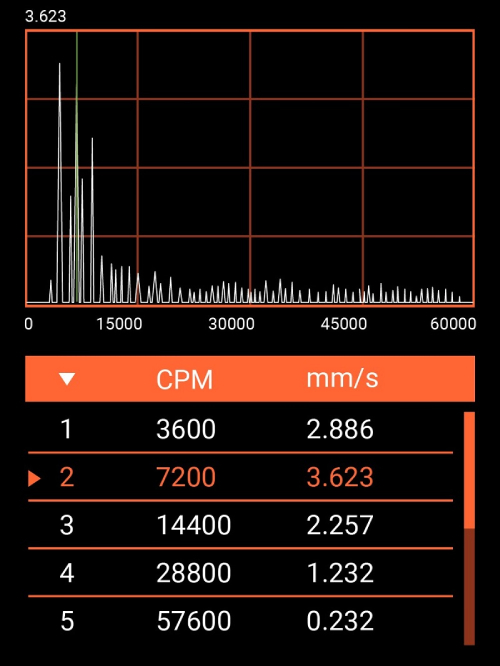

Spectrum Measurement Function (optional)

With the optional spectrum measurement function, the vPod Pro can measure 1 kHz (1600 spectra) or 10 kHz (6400 spectra) for initial vibration diagnosis.

Bluetooth Listening Assessment (standard)

The vPod Pro connects to a Bluetooth headset and automatically plays the original vibration signal for more than two seconds after each measurement through the Bluetooth headset or speaker. This listening feature helps users understand the operation of the device in a more intuitive way.

Camera Features (Standard)

Each vPod Pro has a built-in camera on the back, allowing you to take a picture of the device on the spot while storing measurement data. It also allows you to attach a picture of the sensor installation location to the stored data for notation purposes.

Scheduling Measurement Function (optional)

The vPod Pro with iSee software can perform a complete predictive maintenance inspection. Data is collected according to a predefined iSee database (route). It is then transferred back to the iSee database to obtain complete information on vibration values, bearing status, temperature, waveform, two spectra, one envelope spectrum, and inverse spectrum (Cepstrum) required to monitor rotating equipment, for all equipment predictive maintenance needs.